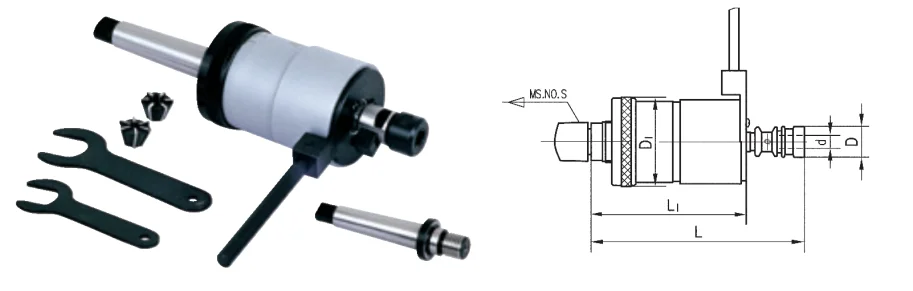

Order No. | Tapping range | d | D | D1 | L | L1 | MS.NO. S |

J467 | M2-M7 | 2.5-6.5 | 23 | 55 | 135 | 95 | MS2-JT33 MS3-JT33 |

J4612 | M5-M12 | 3.5-10 | 28 | 75 | 164 | 114.5 | MS3-M16 MS4-M16 |

J4620 | M8-M20 | 6.0-14 | 38 | 90.5 | 205 | 135 | MS3-M20 MS4-M20 |

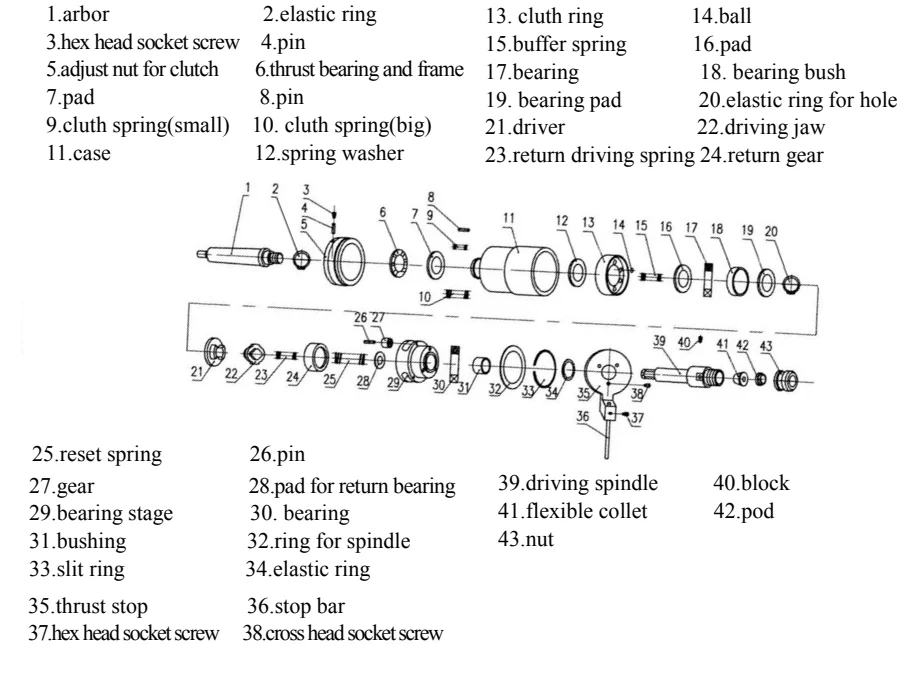

Name of parts:

Method and step:

A. Mounting the chuck: Clean up the connecting parts of both the adaptor and the chuck and mount them onto the machine spindle after they have been assembled.

B. Mounting the tap: Insert the tap into the chuck while watching the position of the tap handle from a window. Then, insert the square end of the tap handle into the square hole of the clamping device and tighten the lock nut with a wrench prior to fastening the top screw of the clamping device.

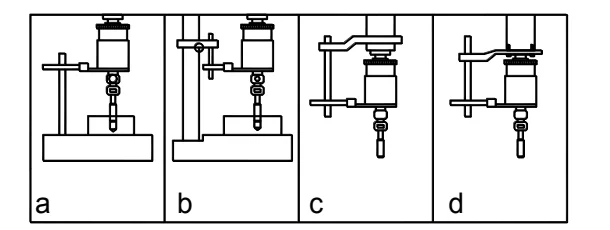

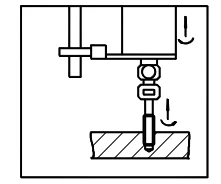

C. Mounting the brake rod: Referring to Figures(1), the brake rod which should be

of a certain rigidity to with stand the torque of a reversing tap(A rod made of steel 45#,

φ 20~30,HRC45 is recommended ) is mounted either on the no rotating part of the spindle end or on the worktable.

a. The brake rod is mounted on the worktable.

b. The brake rod is mounted on the column of the machine tool.

c. The brake rod is mounted on the spindle quill.

d. The brake rod is mounted on the flange of the spindle quill end

D. Adjusting the torque: A proper torque shown with numbers 1,2,3,4 on the main body periphery is selected according to the diameter to be topped and the material of the work piece, showing that the chuck can stand the torque varies form small to large and can be selected by the operator himself. In case of materials which are difficult to be tapped, two operations are recommended.

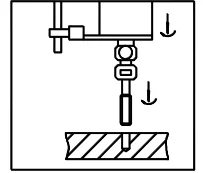

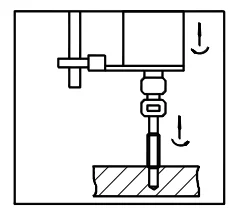

E. Tapping: The operator should align the tap mounted on the machine tool with the machined

screw blank hole on the work piece and operate

referring to Figures.

1. Lower the spindle to make the tap get contact with the work piece, and ready to be cutting.

2. Star tapping, with the machine spindle moving down along with the chuck.

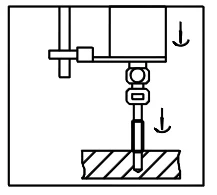

3 Stop the axial movement of the machine spindle upon approaching to the desired depth, meantime the chuck spindle will continue to tap until the extended amount of chuck is reached, then it is automatically stopped to rotate.

4 Raise the machine tool spindle, then the chuck spindle and the tap is automatically rotated in reversibly direction and retreated rapidly.

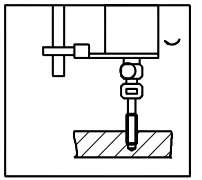

5 The raising of the machine spindle should be in correspondence with the retreating speed of the tap. Otherwise, the tap will stop at one time and act at another time.

6 The tap starts a positive rotation as soon as it has fully with draw from the work piece.